LASER WELDING

Transforming Laser Technology

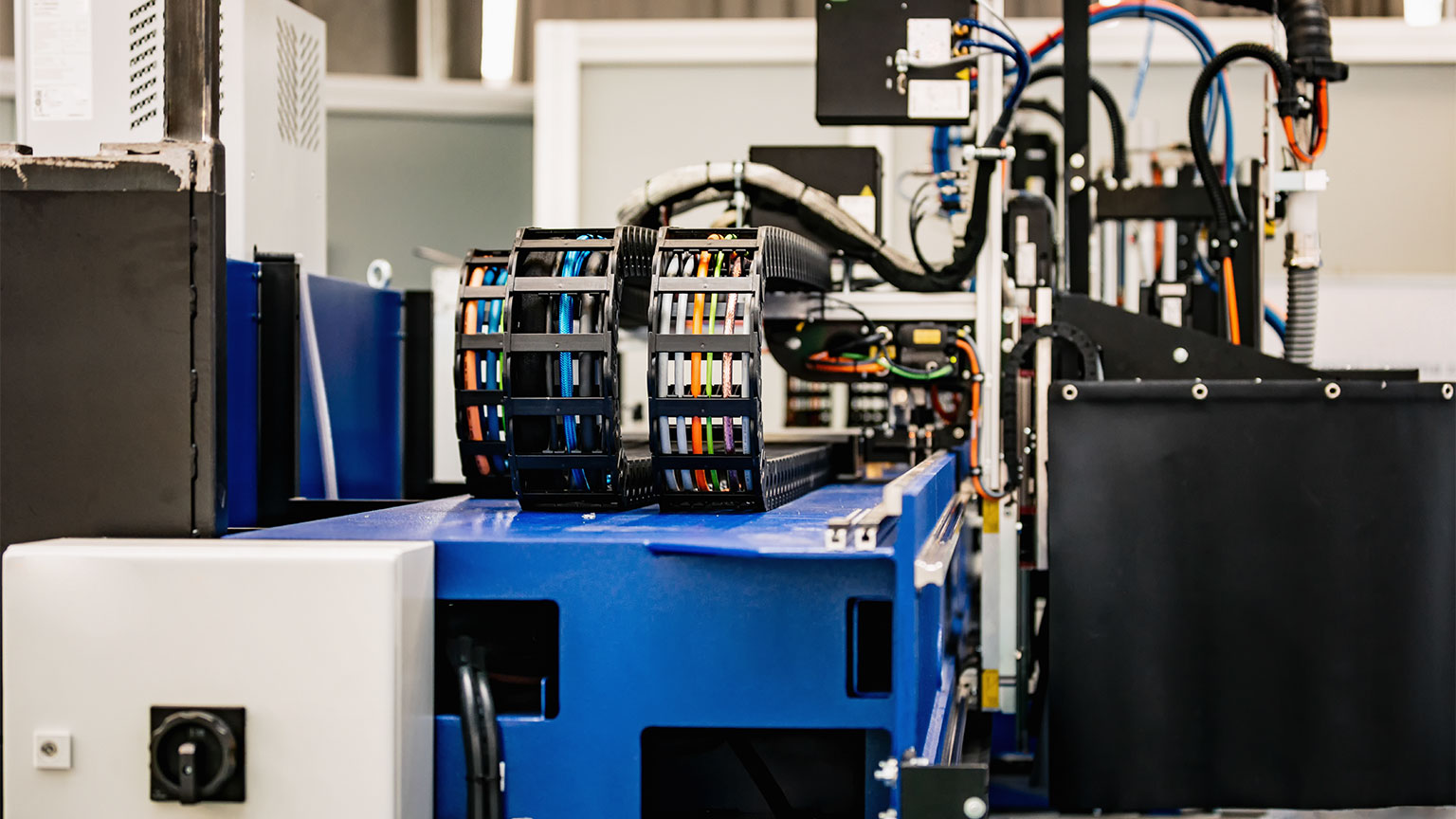

We offer the perfect synergy of experience, automation technology, and scale to advance factory automation and laser integrated solutions for the world’s leading manufacturers.

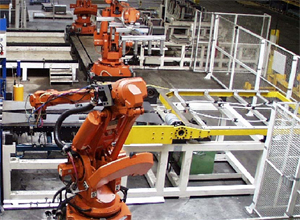

Automated Laser specializes in uniquely customized laser welding systems for plastic and metals, offering precision production systems like no other. We have engineered and designed hundreds of custom application systems to do any kind of laser welding that you can imagine. Our engineering team is creative, resourceful and we have years of experience and expertise in laser welding design applications, programming, and final process operation. We can custom design a simple manual load, single process cell or deliver a complex system integrating multiple stations, part assembly, material handling, testing and so much more.

Tailor Blank Welding

Tailored blanks are semi-finished parts, which are typically made from sheets with different alloys, thicknesses, coatings or material properties. After joining, these will be subjected to deep drawing or stamping….

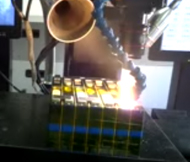

Battery Welding

Laser welding is widely used in the sealing of batteries shell, stainless or aluminum. Fiber transferring make it fit for working with manufacturing lines and realizing welding automation. Unite Winner’s laser welding machines are now used in famous battery factories like BYD….

Pillow Welding

The Pillow Plate (or thermo plate) consists of two steel plates, connected by laser welding. After being welded together, the plate is inflated by using water pressure. The water pressure creates a specific single or double embossed profile – the pillow plate, through which the cooling or heating medium is conducted….

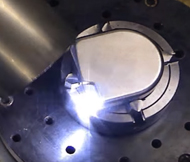

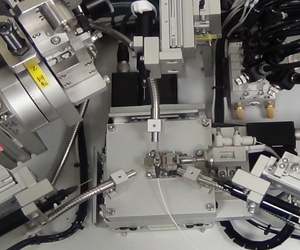

Glovebox (eg. Pace maker)

We manufacture & supply an excellent assortment of our Glove Box Welding Machines, which is widely accepted by our clients all across the globe. Our such range is fabricated from high grade material that makes it more reliable and durable. These machines are very efficient as they are built using advanced technology….

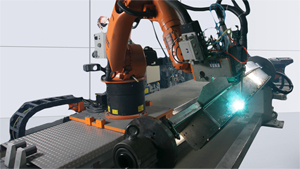

Hybrid Laser Welding

Laser Hybrid welding is a type of welding process that combines the principles of laser beam welding and arc welding.The combination of laser light and an electrical arc into an amalgamated welding process has existed since the 1970s, but has only recently been used in industrial applications. There are three main types….

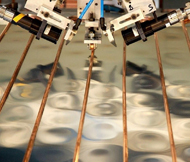

Solar Panel Welding

For flat plate solar energy collectors, the aluminium sheet and copper tube is thin, traditional welding will cause irregularity in welding depth, blemish, and destroying the covering film of the collector. Laser welding will solve this problem for its precise locating….

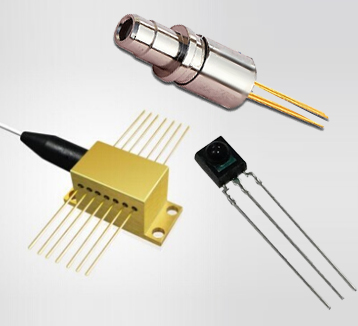

Opto Communication

Pulse laser welders are electronically compatible and ideal for voltage sensitive applications. Precision automated or manual welding construction can be performed on electronic/industrial components with a high degree of accuracy, while eliminating the potential hazards of heat damage or thermal stress to complex manufacturing….

Mould Laser Welding

The working principle of this laser deposition welding system is to use laser high thermal energy and the melting technology in spot to process the welding and repairing of minute parts. It makes up the shortage of traditional hydrogen arc welding in repairing precision surfaces, avoids the two difficulties of thermal strain and….

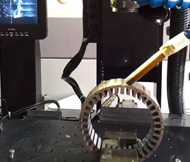

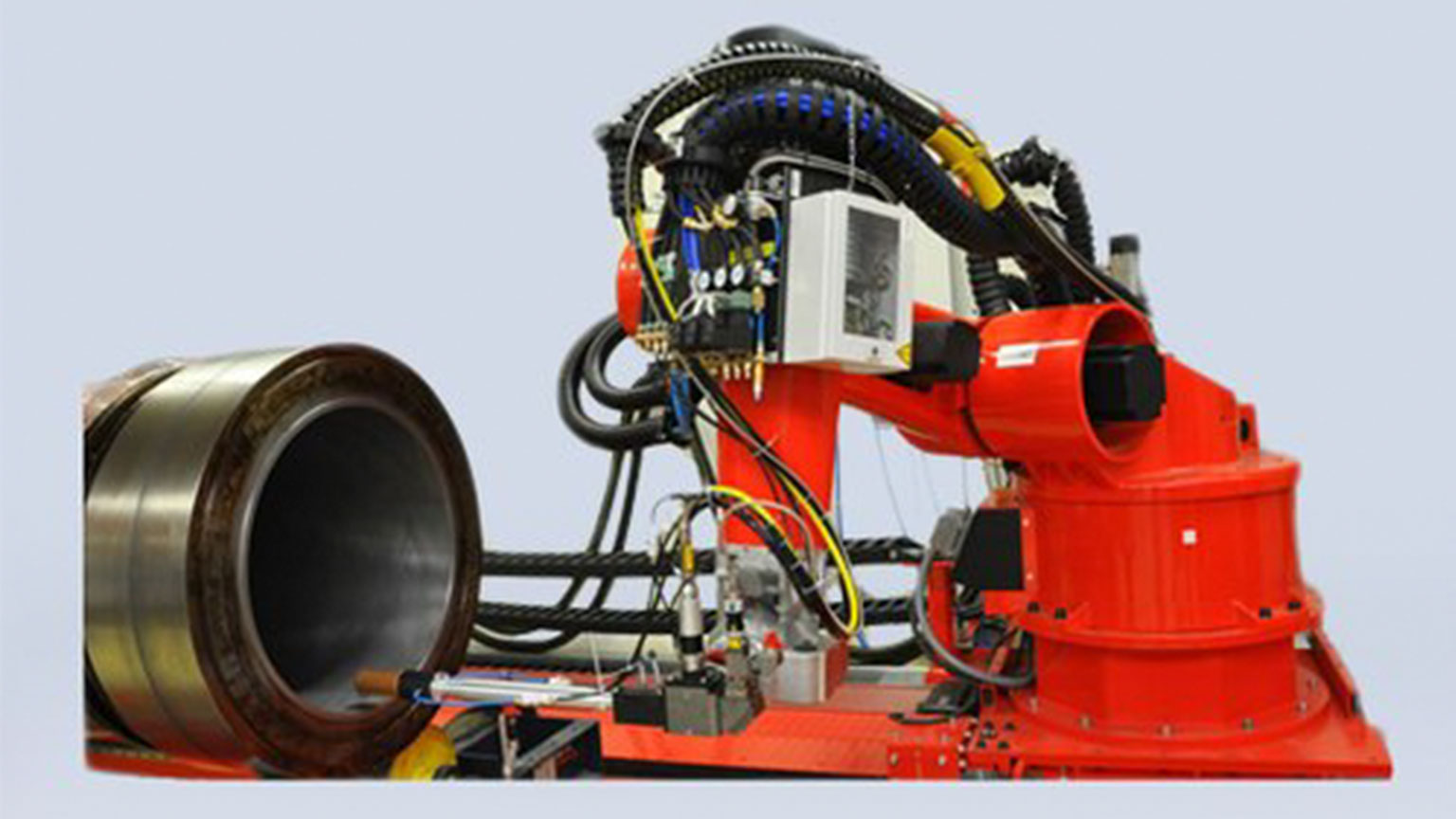

Electro Motor Welding

From welding of special gears for small batches of gearboxes, to rack-and-pinion steering gear, differentials, cylinder blocks, suspension arm strengthening ribs and advanced devices at the cutting edge of racing technology, you can depend on us to keep your team in pole position. We weld aluminum alloys….

Laser Jewelry Spot Welding

The laser spot welding is an important aspect of laser process technology application. The spot welding process is thermal conduction, i.e. the laser radiation heats the surface of work piece, and the surface heat diffuses to the interior through thermal conduction and melts the work piece by controlling the width, energy, peak….

Plastic Welding

This technique requires one part to be transmissive to a laser beam and either the other part absorptive or a coating at the interface to be absorptive to the beam. The two parts are put under pressure while the laser beam moves along the joining line. The beam passes through the first part and is absorbed by the other ….

From welding of special gears for small batches of gearboxes, to rack-and-pinion steering gear, differentials, cylinder blocks, suspension arm strengthening ribs and advanced devices at the cutting edge of racing technology, you can depend on us to keep your team in pole position. We weld aluminum alloys, steel and titanium and resolve your high-tech welding issues. Prototype work is frequently undertaken.

From welding of special gears for small batches of gearboxes, to rack-and-pinion steering gear, differentials, cylinder blocks, suspension arm strengthening ribs and advanced devices at the cutting edge of racing technology, you can depend on us to keep your team in pole position. We weld aluminum alloys, steel and titanium and resolve your high-tech welding issues. Prototype work is frequently undertaken.

The laser spot welding is an important aspect of laser process technology application. The spot welding process is thermal conduction, i.e. the laser radiation heats the surface of work piece, and the surface heat diffuses to the interior through thermal conduction and melts the work piece by controlling the width, energy, peak power and repeating frequency of laser pulse to form specific molten pool. Because of its unique advantage, it is widely used in the process of gold and silver jewelry and welding of mini and small parts.

The laser spot welding is an important aspect of laser process technology application. The spot welding process is thermal conduction, i.e. the laser radiation heats the surface of work piece, and the surface heat diffuses to the interior through thermal conduction and melts the work piece by controlling the width, energy, peak power and repeating frequency of laser pulse to form specific molten pool. Because of its unique advantage, it is widely used in the process of gold and silver jewelry and welding of mini and small parts. Pulse laser welders are electronically compatible and ideal for voltage sensitive applications. Precision automated or manual welding construction can be performed on electronic/industrial components with a high degree of accuracy, while eliminating the potential hazards of heat damage or thermal stress to complex manufacturing materials.

Pulse laser welders are electronically compatible and ideal for voltage sensitive applications. Precision automated or manual welding construction can be performed on electronic/industrial components with a high degree of accuracy, while eliminating the potential hazards of heat damage or thermal stress to complex manufacturing materials. For flat plate solar energy collectors, the aluminium sheet and copper tube is thin, traditional welding will cause irregularity in welding depth, blemish, and destroying the covering film of the collector.

For flat plate solar energy collectors, the aluminium sheet and copper tube is thin, traditional welding will cause irregularity in welding depth, blemish, and destroying the covering film of the collector. Laser Hybrid welding is a type of welding process that combines the principles of laser beam welding and arc welding. The combination of laser light and an electrical arc into an amalgamated welding process has existed since the 1970s, but has only recently been used in industrial applications.

Laser Hybrid welding is a type of welding process that combines the principles of laser beam welding and arc welding. The combination of laser light and an electrical arc into an amalgamated welding process has existed since the 1970s, but has only recently been used in industrial applications. We manufacture & supply an excellent assortment of our Glove Box Welding Machines, which is widely accepted by our clients all across the globe. Our such range is fabricated from high grade material that makes it more reliable and durable. These machines are very efficient as they are built using advanced technology.

We manufacture & supply an excellent assortment of our Glove Box Welding Machines, which is widely accepted by our clients all across the globe. Our such range is fabricated from high grade material that makes it more reliable and durable. These machines are very efficient as they are built using advanced technology. The Pillow Plate (or thermo plate) consists of two steel plates, connected by laser welding. After being welded together, the plate is inflated by using water pressure. The water pressure creates a specific single or double embossed profile – the pillow plate, through which the cooling or heating medium is conducted. While the thickness and the spot pattern is determined by the design pressure.

The Pillow Plate (or thermo plate) consists of two steel plates, connected by laser welding. After being welded together, the plate is inflated by using water pressure. The water pressure creates a specific single or double embossed profile – the pillow plate, through which the cooling or heating medium is conducted. While the thickness and the spot pattern is determined by the design pressure. Tailored blanks are semi-finished parts, which are typically made from sheets with different alloys, thicknesses, coatings or material properties. After joining, these will be subjected to deep drawing or stamping.

Tailored blanks are semi-finished parts, which are typically made from sheets with different alloys, thicknesses, coatings or material properties. After joining, these will be subjected to deep drawing or stamping.

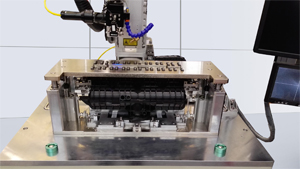

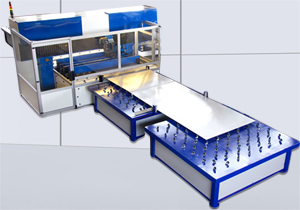

It incorporates space saving design and ease of use. Its high cutting speed and very low operating cost makes the most affordable system on the market. The Lasersystem can cut both framed and frameless stencils, without requiring any changeover. The light weight motion system allows excellent positioning accuracy while maintaining cutting speeds that are the highest in its class.

It incorporates space saving design and ease of use. Its high cutting speed and very low operating cost makes the most affordable system on the market. The Lasersystem can cut both framed and frameless stencils, without requiring any changeover. The light weight motion system allows excellent positioning accuracy while maintaining cutting speeds that are the highest in its class.