LASER WELDING

Transforming Laser Technology

We offer the perfect synergy of experience, automation technology, and scale to advance factory automation and laser integrated solutions for the world’s leading manufacturers.

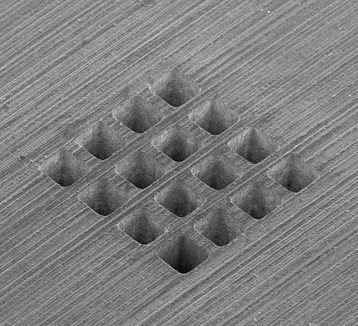

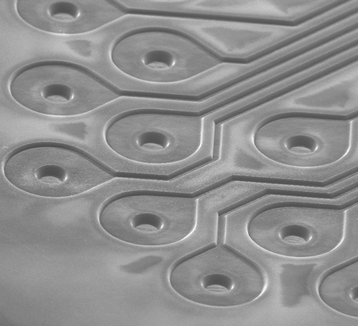

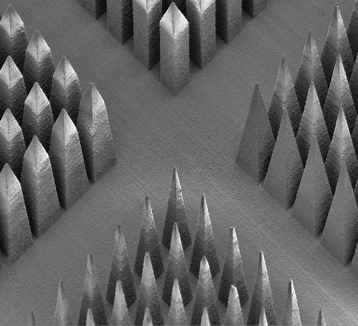

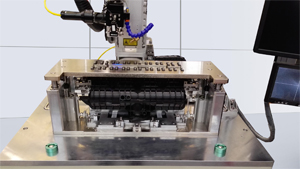

Micromachining Division supplies full turnkey laser micromachining systems for laser drilling, cutting, marking, patterning, milling, and ablation. A variety of configurations are offered which can incorporate DPSS nanosecond, picosecond or femtosecond lasers operating in the IR, visible and UV to give controlled ablation of a wide range of materials. Lasers standard systems range from tabletop general machining advanced research and development to high commercial production solutions.

Important value-added features of our system integration include:

- Onsite installation, commissioning and training

- Drop in the power consumption Technical consulting

- On-going technical after sale and applications support

- Few microns of waste material

LPS Series of laser system for reliable Laser Machining

A typical example of laser system integration is the LPS Series easy to use and compact to conserve valuable floorspace. Typical applications include silicon wafer coring/resizing, solar cell micromachining and cutting/drilling/grooving thin metals and ceramics for all sorts of applications including medical.

Important features of the LPS-300 system

1. Through-the-Lens Viewing:

The LPS-300 features video viewing for a magnified image of work in progress. A video camera looks through the laser focusing lens – a similar principle to an SLR camera or a rifle scope. It simplifies and speeds up alignment of each part, facilitates high yields, and targets laser impact. But most important – it provides both sharp visual human focus and sharp laser beam focus which otherwise would be at different places because of chromatic aberration. Magnification is 60X, twenty times more powerful than opera glasses.

2. Three-Axis Computer Controlled System

Our standard design is 3-axis which increases the versatility of the laser machine. Parts having different thicknesses can be rapidly inserted in the machine.

3. Computer Controlled Focal Point

A method of rapid and reliable control of laser spot size is by the computer driving the motorized beam expanding telescope. This works by placing the laser focus quickly at desired distances above and below the top surface of the part, which does not change the operator’s visual plane of focus so the part remains in sharp focus to the human eye.

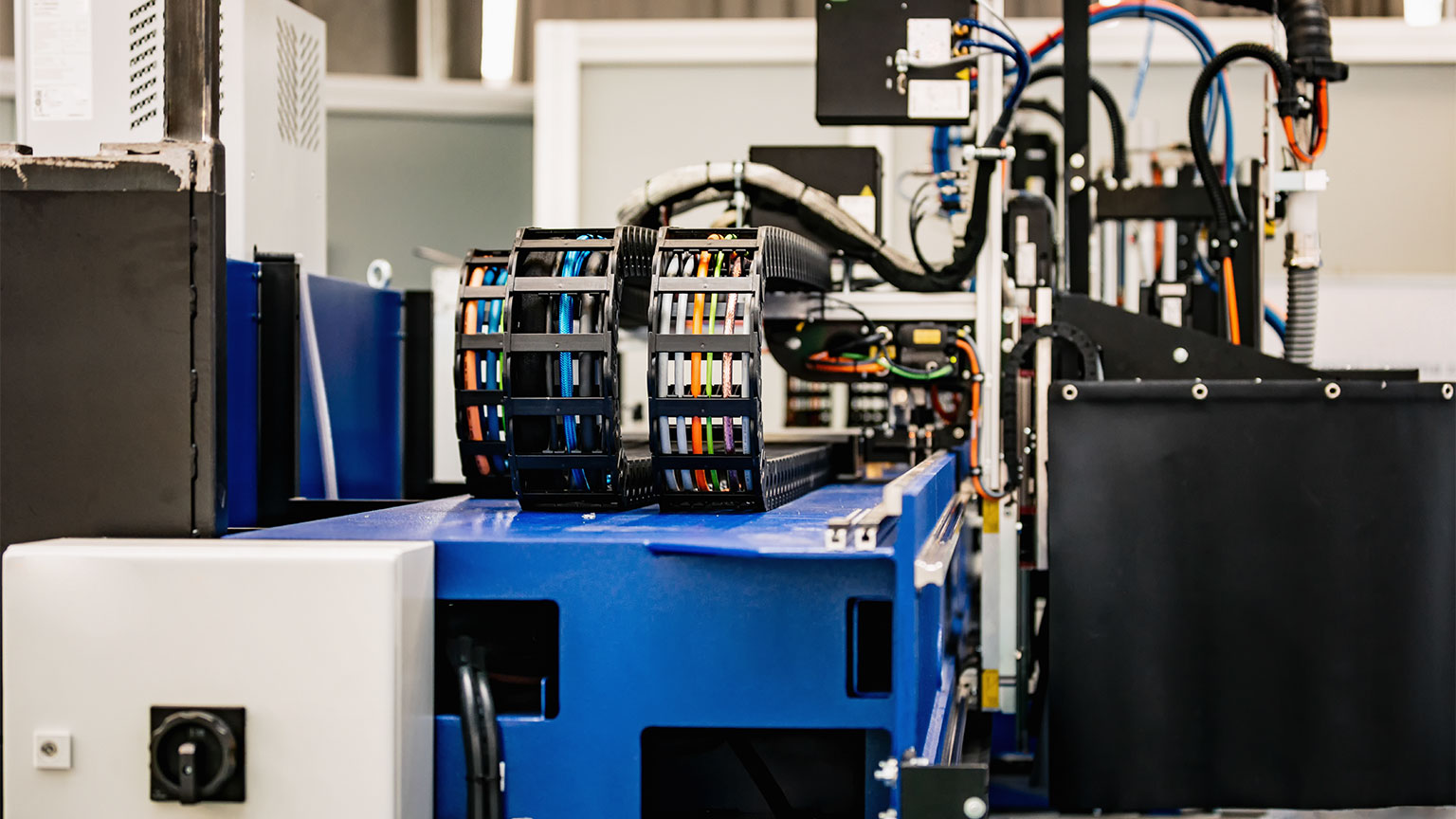

Laserod system components & options - OVERVIEW(statement of capabilities)

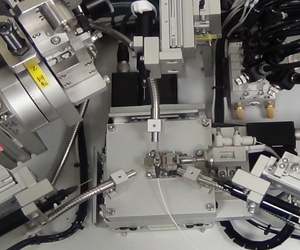

We integrate lasers, motion devices, computer hardware, power distribution drawer or box, software and optics into a fully functional laser machining tool. It goes without saying that “Know How” is our stock in trade.

We suggest you have us prototype first as proof of principle, then run lots to prove out performance, throughput, and quality.

Laser Engines Supplied:

- fiber (solid-state)

- diode(solid-state)

- lamp (solid-state)

- sealed CO2 (gas)

- excimers (gas)

- Picosecond (ps) (solid-state)

Laser Wavelengths: UV to IR, ranging from 0.355 to 10.6 microns

Beam Directing and Shaping Optics:

- Galvanometer (galvo) or fixed beam or gantry O\overhead moving beam

- On-axis, in-line viewing is standard with fixed beam optics

- Off-axis viewing as galvo option

- Air bearing Z-follower for 3D random terrain following as option to fixed beam optics

- Dual beam-split beam optics as option to fixed beam optics

Motion Devices:

- Galvo to move beam, 2- or 3-axis

- X-Y stage to move part

- X-Y-Z stage, X-Y for part, Z for beam

- Combination galvo and X-Y, a 4- or 5-axis motion system

- As X-Y stage options, crossed roller bearing, air-bearing, linear optical encoders, crossed roller bearings with linear motors, and air-bearings with linear motors and optical encoders

- Rotary parts motion

- Roll-to-Roll web converters

Structures:

Supporting frames of welded steel and light weight extruded aluminum. Mounting plates of anodized aluminum or granite

Computer:

PC with software optimized for your application. CADCAM as option

Function:

- Production

- Prototype

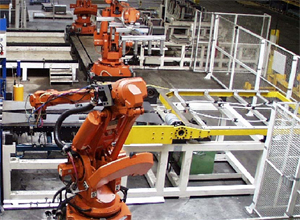

- Robotics, machine vision, parts handling, automation controls for conveyor belt, parts loader, web, etc.

Note: We select components to optimize both application and budget.

List of Jobs Done by Solid-State Lasers:

- IR medium power diode: all thin metals, some rubber and some plastics – also thin

- Low power diode: IR, green or UV for display patterning, resistor trimming, marking, UV for 10um holes or patterns etched on coatings on glass or plastic substrates.

- IR high power fiber: robust parts that the high pressure air won’t blow away or damage such as silicon wafers, solar cells and ceramic substrate resizing at high speeds

- IR low power fiber: patterning thin coatings on glass or plastic substrates at high speed

Component Modules in a Typical Laser System:

Laser System with highlighted beam delivery optics:

The Laserod modular Work Station comprises laser + housing + optics (including motorized computer controlled telescope and Z) + XY table + PC + software + electronics cabinet + safety enclosure + options (fixtures, gas jet nozzle, vacuum exhaust, gas blanket, robotics, etc.)

Modules Include:

- SOFTWARE – provides customized screen shot with G type code for your operator’s convenience and optional Picture to Part dxf download direct to the laser machine.

- Optics head for fixed laser beam delivery with video viewing — includes beam bender, focuser, safety cover, and focuser with optional gas jet nozzle. Magnified TV viewing standard.

- Optics head for galvo beam delivery — includes beam bender, focuser, safety cover, focuser with gas jet option. Off-axis or frozen mirror video viewing optional

- Beam expanding laser telescope – zoom expansion ratio 3X to 5X. Larger expansion ratios and motorized feature are available. Historically, we have always chosen the expansion ratio.

- Laser head housing to contain your laser “engine”, plus the telescope and optics head. Provides CDRH Class 1 light tight seal

- Gas jet nozzle — utilizes air pressure to assist laser cutting

- X-Y translating stage — move the part with fixed beam

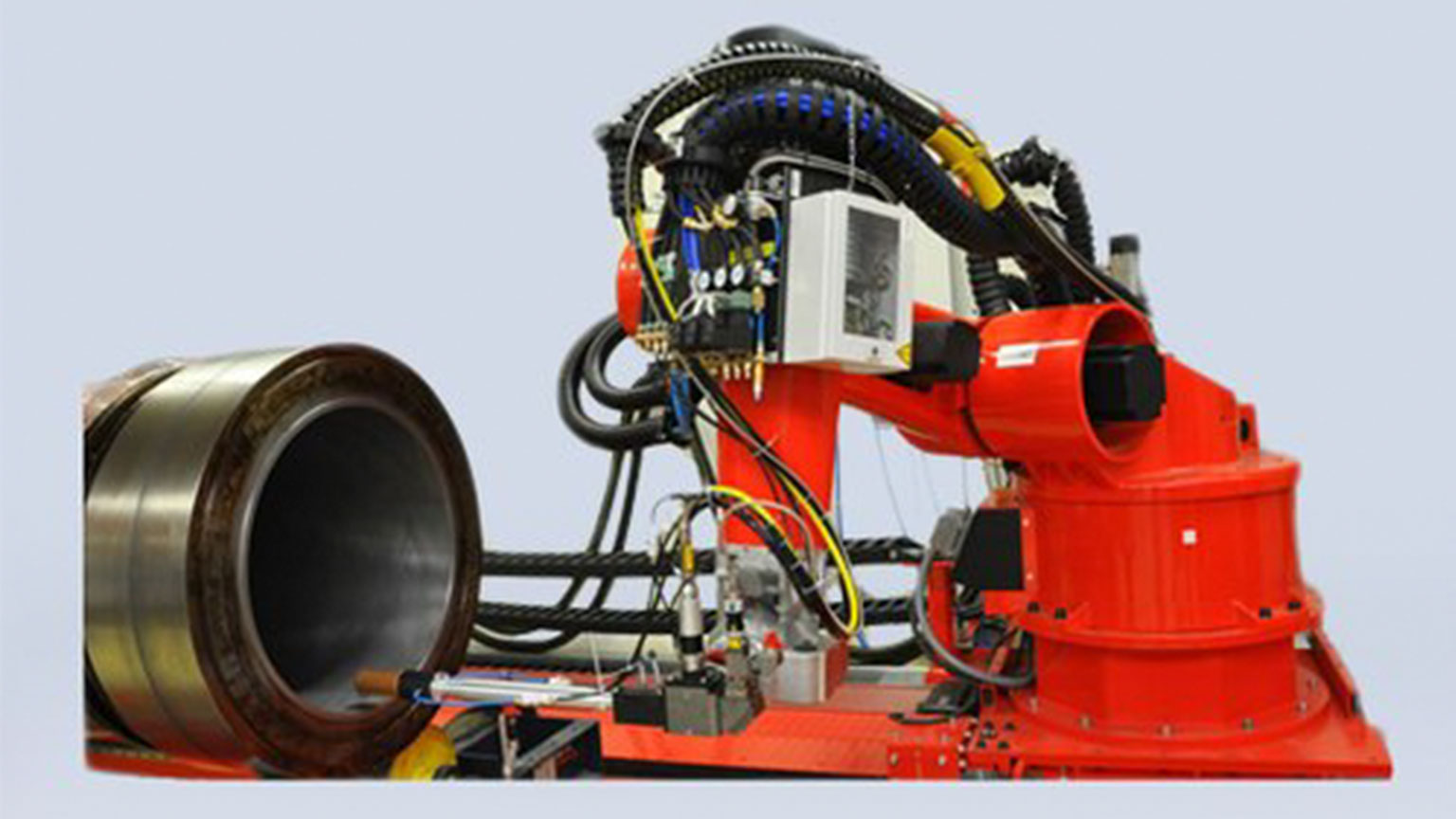

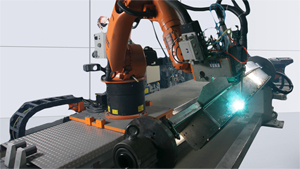

From welding of special gears for small batches of gearboxes, to rack-and-pinion steering gear, differentials, cylinder blocks, suspension arm strengthening ribs and advanced devices at the cutting edge of racing technology, you can depend on us to keep your team in pole position. We weld aluminum alloys, steel and titanium and resolve your high-tech welding issues. Prototype work is frequently undertaken.

From welding of special gears for small batches of gearboxes, to rack-and-pinion steering gear, differentials, cylinder blocks, suspension arm strengthening ribs and advanced devices at the cutting edge of racing technology, you can depend on us to keep your team in pole position. We weld aluminum alloys, steel and titanium and resolve your high-tech welding issues. Prototype work is frequently undertaken.

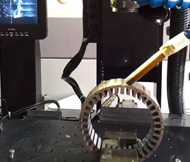

Standard motors have straight plain output shafts, and need gears or actuators welding on. Laser welding is ideal for its accuracy in aligning the gear and welding it firmly in place, and the low heat input avoids damaging the motor. Cars weld front wing trim actuators and gear selector motors for various teams.

Standard motors have straight plain output shafts, and need gears or actuators welding on. Laser welding is ideal for its accuracy in aligning the gear and welding it firmly in place, and the low heat input avoids damaging the motor. Cars weld front wing trim actuators and gear selector motors for various teams.

The laser spot welding is an important aspect of laser process technology application. The spot welding process is thermal conduction, i.e. the laser radiation heats the surface of work piece, and the surface heat diffuses to the interior through thermal conduction and melts the work piece by controlling the width, energy, peak power and repeating frequency of laser pulse to form specific molten pool. Because of its unique advantage, it is widely used in the process of gold and silver jewelry and welding of mini and small parts.

The laser spot welding is an important aspect of laser process technology application. The spot welding process is thermal conduction, i.e. the laser radiation heats the surface of work piece, and the surface heat diffuses to the interior through thermal conduction and melts the work piece by controlling the width, energy, peak power and repeating frequency of laser pulse to form specific molten pool. Because of its unique advantage, it is widely used in the process of gold and silver jewelry and welding of mini and small parts. Pulse laser welders are electronically compatible and ideal for voltage sensitive applications. Precision automated or manual welding construction can be performed on electronic/industrial components with a high degree of accuracy, while eliminating the potential hazards of heat damage or thermal stress to complex manufacturing materials.

Pulse laser welders are electronically compatible and ideal for voltage sensitive applications. Precision automated or manual welding construction can be performed on electronic/industrial components with a high degree of accuracy, while eliminating the potential hazards of heat damage or thermal stress to complex manufacturing materials. For flat plate solar energy collectors, the aluminium sheet and copper tube is thin, traditional welding will cause irregularity in welding depth, blemish, and destroying the covering film of the collector.

For flat plate solar energy collectors, the aluminium sheet and copper tube is thin, traditional welding will cause irregularity in welding depth, blemish, and destroying the covering film of the collector. Laser Hybrid welding is a type of welding process that combines the principles of laser beam welding and arc welding. The combination of laser light and an electrical arc into an amalgamated welding process has existed since the 1970s, but has only recently been used in industrial applications.

Laser Hybrid welding is a type of welding process that combines the principles of laser beam welding and arc welding. The combination of laser light and an electrical arc into an amalgamated welding process has existed since the 1970s, but has only recently been used in industrial applications. We manufacture & supply an excellent assortment of our Glove Box Welding Machines, which is widely accepted by our clients all across the globe. Our such range is fabricated from high grade material that makes it more reliable and durable. These machines are very efficient as they are built using advanced technology.

We manufacture & supply an excellent assortment of our Glove Box Welding Machines, which is widely accepted by our clients all across the globe. Our such range is fabricated from high grade material that makes it more reliable and durable. These machines are very efficient as they are built using advanced technology. The Pillow Plate (or thermo plate) consists of two steel plates, connected by laser welding. After being welded together, the plate is inflated by using water pressure. The water pressure creates a specific single or double embossed profile – the pillow plate, through which the cooling or heating medium is conducted. While the thickness and the spot pattern is determined by the design pressure.

The Pillow Plate (or thermo plate) consists of two steel plates, connected by laser welding. After being welded together, the plate is inflated by using water pressure. The water pressure creates a specific single or double embossed profile – the pillow plate, through which the cooling or heating medium is conducted. While the thickness and the spot pattern is determined by the design pressure. Tailored blanks are semi-finished parts, which are typically made from sheets with different alloys, thicknesses, coatings or material properties. After joining, these will be subjected to deep drawing or stamping.

Tailored blanks are semi-finished parts, which are typically made from sheets with different alloys, thicknesses, coatings or material properties. After joining, these will be subjected to deep drawing or stamping.

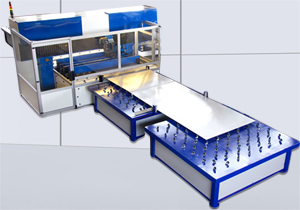

It incorporates space saving design and ease of use. Its high cutting speed and very low operating cost makes the most affordable system on the market. The Lasersystem can cut both framed and frameless stencils, without requiring any changeover. The light weight motion system allows excellent positioning accuracy while maintaining cutting speeds that are the highest in its class.

It incorporates space saving design and ease of use. Its high cutting speed and very low operating cost makes the most affordable system on the market. The Lasersystem can cut both framed and frameless stencils, without requiring any changeover. The light weight motion system allows excellent positioning accuracy while maintaining cutting speeds that are the highest in its class.