Semiconductor pump series laser marker uses Galvanometer laser marking technology and most advanced semiconductor pump laser technology, makes the YAG rod generates a mass of inverted population with 800nm wavelength semiconductor laser diode pump Nd:YAG crystal, forms 1064nm wavelength giant pulse laser beam output under the effect of 0 switch, through expanding and focusing of laser beam, and finally realizes marking through controlling the deflection of galvanometer.

It is a revolution in laser marking field. This type of laser marker features low energy consumption, high electro-optic conversion efficiency, stable laser output mode, high reliability, small size, excellent marking effect and no consumables.

The marker is designed according to ergonomics, providing beautiful appearance and simple operation. All the important optic parts are imported from Europe and America. The optics system is in fully sealed structure. It has optics preview and focus indication function and provides reliable security for the 24-hour continuous working of the machine.

| S.No | Parameters Name | Parameters Data |

|---|---|---|

| 1. | Max. laser average power | 50W |

| 2. | Beam quality | <6M2 |

| 3. | Laser wavelength | 1064nm |

| 4. | Repetition frequency | ≤50KHz |

| 5. | Cooling Mode | Water-cooling |

| 6. | Standard marking area | 100mm×100mm |

| 7. | Marking area option | 50mm×50mm, 150mm×150mm, 200mm×200mm, 300mm×300mm |

| 8. | Marking depth | ≤1.8mm |

| 9. | Linear speed | ≤7000mm/s |

| 10. | Min. line width | 0.01mm |

| 11. | Min. character size | 0.2mm |

| 12. | Repetition accuracy | ±0.002mm |

| 13. | Power consumpted | ≤1.5KW |

Semiconductor lasers are diodes which are electrically pumped. Recombination of electrons and holes created by the applied current introduces optical gain. Reflection from the ends of the crystal form an optical resonator, although the resonator can be external to the semiconductor in some designs.

| S.No | Parameters Name | Parameters Data |

|---|---|---|

| 1. | Max. laser average power | 30W |

| 2. | Repeat accuracy | 0.001mm |

| 3. | Laser wavelength | 1064nm |

| 4. | Repetition frequency | ≤50KHz |

| 5. | Cooling Mode | Water-cooling |

| 6. | Standard marking area | 100mm×100mm |

| 7. | Marking area option | 50mm×50mm, 150mm×150mm, 200mm×200mm, 300mm×300mm |

| 8. | Marking depth | ≤1.8mm |

| 9. | Linear speed | ≤7000mm/s |

| 10. | Min. line width | 0.01mm |

| 11. | Min. character size | 0.2mm |

| 12. | Repetition accuracy | ±0.002mm |

The optical fiber laser marker is the third generation laser marker system developed by our company with the most advanced technology in the world. It uses optical fiber laser to output laser and realizes marking function through high speed scanning galvanometer system. The optical fiber laser marker features high electro optic conversion efficiency, air cooling, small size, high quality output beam, high reliability, long service life and energy saving.

It can carve metal materials and certain nonmetal materials and is widely used in fields that have high requirement on depth, smoothness and fine, such as stainless steel mobile phone overlay, clock and watch, mould, IC, mobile phone keypad, etc. Bit map marking can carve beautiful pictures on the surfaces of metal and plastic, and the marking speed is 3-12 times of the speed of traditional first generation lamp pump marker and second generation semiconductor marker.

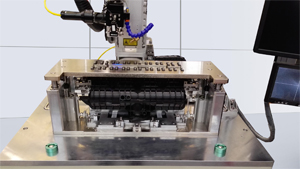

10W Air DPSS OEM in a new Nd:YVO4 laser marker system which can work on any type of metal and almost all industrial use plastics. The system consists of two parts: resonator unit-scnaeer head and power supply box and control. A 3 m optical fivre and signeal cable allow the power supply box to operate remotely. A notebook with the customs interface card and SLC (MLS LASER CONTROLLER).

| S.No | Parameters Name | Parameters Data |

|---|---|---|

| 1. | Output power | 10W @ 10KHz |

| 2. | Wavelength | 1064nm |

| 3. | M2 | ≤1,8 |

| 4. | Max. marking speed | 5000 mm/s |

| 5. | Power supply | 230V 50/60 Hz 1ph |

| 6. | Absorbed power | 550 W |

| 7. | Beam source weight | 5 Kgs |

| 8. | Scanner head weight | 3 Kgs |

| 9. | Aiming beam | Red Diode Lase |

| 10. | Marking area | 65×65 mm and 110×110 mm |

Laser marking systems provide a galvo-steered beam designed for marking. The CO-Series laser marking systems are excellent for marking substrates like wood, glass, Plexiglas®, quartz, ceramics, fabrics, and other organic materials. Mark-On-The-Fly versions are available for application dependent line speeds up to 2700 ft/min. (900 meters per minute). Also available are embedded controller versions requiring no separate PC

| S.No | Parameters Name | Parameters Data |

|---|---|---|

| 1. | Laser Type | CO2 |

| 2. | Laser wavelength | 1064nm |

| 3. | Max. Pulse Frequency | 50kHz |

| 4. | Max. Marking Speed | 5,000mms-1 |

| 5. | Operating Temperature | 16°C – 35°C (Non Condensing) |

| 6. | Max. Laser Average Power | 30W, 55W |

| 7. | Pulse Duration | 20µs |

| 8. | Power Stability | 5% |

| 9. | Beam Quality | >15mm.mrad |

| 10. | Control Electronics | 19 inch rack mounted (5U) |

| 11. | Optical Unit Protection | IP52A |

| 12. | Supply Requirement | 5KW |

| 13. | Max. Weight | 56Kg |

YAG laser is a kind of solid laser and the wavelength of the laser that it generates is 1064nm, which is in infrared frequency. It features high resonance efficiency, high output power and high stability. It is the most mature and mostly used solid laser. The lamp pump YAG laser uses the krypton lamp as the energy source and Nd:YAG as the medium (working substance) that generates laser.

The light of specific wavelength that the excitation source generates can promote the working substance to have level jump and release laser. After amplifying the released laser energy, the laser beam that can process materials is formed.

| S.No | Parameters Name | Parameters Data |

|---|---|---|

| 1. | Laser wavelength | 1064nm |

| 2. | Laser repeating precision | ≤50KHz |

| 3. | Maximum laser power | 50W |

| 4. | Standard carving range | 100mm*100mm |

| 5. | Optional carving range | 50mm*50mm |

| 6. | Carving depth | <1mm |

| 7. | Carving line speed | ≤7000mm/s |

| 8. | Minimum line width | 0.015mm |

| 9. | Minimum character | 0.3mm |

| 10. | Repeating precision | ±0.003mm |

| 11. | Power supply | 220V/single/50Hz/20A |

| 12. | Integrity power | 5KW |

Solid-state (DPSS) green wavelength laser marking system. The laser beam and Q-switched pulse characteristics are optimized for applications that require high beam quality and stability. In addition, the EV4GDS offers extra power and speed for precision marking, and is the ideal choice for laser marking, scribing, trimming and other material processing applications. With an average diode life of greater than 20,000 working hours, the EV4GDS offers the user “best-in-class” reliability. The robust mechanical and optical design of the Telesis EV4GDS enables operation in an industrial environment where shock, vibration, and dust are a concern. Power Range: 4W

| S.No | Parameters Name | Parameters Data |

|---|---|---|

| 1. | Laser wavelength | 532nm |

| 2. | Light beam quality | <2 |

| 3. | Power | 5W/7W/9W |

| 4. | Repeating frequency | 0-100KHZ |

| 5. | Carving range | 70×70mm/ 100×100mm |

| 6. | Carving line speed | ≤7000mm/s |

| 7. | Minimum character | 0.15mm |

| 8. | Repeating precision | ±0.004 |

| 9. | Cooling method | Air cooling |

| 10. | Power supply | 220V/50HZ/10A |

This technique requires one part to be transmissive to a laser beam and either the other part absorptive or a coating at the interface to be absorptive to the beam. The two parts are put under pressure while the laser beam moves along the joining line.

The beam passes through the first part and is absorbed by the other one or the coating to generate enough heat to soften the interface creating a permanent weld.

Semiconductor diode lasers are typically used in plastic welding. Wavelengths in the range of 808 nm to 980 nm can be used to join various plastic material combinations. Power levels from less than 1W to 100W are needed depending on the materials, thickness and desired process speed.

New fiber laser technology allows for the output of longer laser wavelengths, with the best results typically around 2,000 nm, significantly longer than the average 808 nm to 1064 nm diode laser used for traditional laser plastic welding.[citation needed] Because these longer wavelengths are more readily absorbed by thermoplastics than the infra-red radiation of traditional plastic welding, it is possible to weld two clear polymers without any colorants or absorbing additives. Common Applications will mostly fall in the medical industry for devices like catheters and microfluidic devices. The heavy use of transparent plastics, especially flexible polymers like TPU, TPE and PVC, in the medical device industry makes transparent laser welding a natural fit. Also, the process requires no laser absorbing additives or colorants making testing and meeting biocompatibility requirements significantly easier.

Specific applications include sealing / welding / joining of: catheter bags, medical containers, automobile remote control keys, heart pacemaker casings, syringe tamper evident joints, headlight or tail-light assemblies, pump housings, and cellular phone parts.

Laser welding is widely used in the sealing of batteries shell, stainless or aluminum. Fiber transferring make it fit for working with manufacturing lines and realizing welding automation. Unite Winner’s laser welding machines are now used in famous battery factories like BYD.

| S.No | Parameters Name | Parameters Data |

|---|---|---|

| 1. | Laser Wavelength | 1064nm |

| 2. | Rated laser output power | 400W |

| 3. | Adjusting range of light spot | 0.1-3.0mm |

| 4. | Size of light spot | 0.2-3.0mm |

| 5. | Pulse width | ≤20ms |

| 6. | Pulse frequency | ≤100Hz |

| 7. | Laser type | Nd:YAG pulse |

| 8. | Sighting positioning method | Semiconductor red light |

| 9. | NC system of the work bench | Mitsubishi PLC |

| 10. | Stroke of work bench | 200*100*150mm (z-axis manual, stroke is optional) |

| 11. | Positioning precision | ±0.02mm |

| 12. | Repeating positioning precision | ±0.01mm |

| 13. | 3-axis stroke of work bench | 200*200mm to 1200*1200mm (optional) |

| 14. | Bearing of work bench | ≤50kg |

| 15. | Power supply | 380V/3-phase/50Hz/40A |

| 16. | Master unit power consumption | 14KW |

The working principle of this laser deposition welding system is to use laser high thermal energy and the melting technology in spot to process the welding and repairing of minute parts. It makes up the shortage of traditional hydrogen arc welding in repairing precision surfaces, avoids the two difficulties of thermal strain and after-treatment, and saves the production period of mould.

The laser deposition welding system (laser mould welder) is specially designed for the mould industry and used in repairing of precision moulds, such as mould manufacture for digital products, mobile phone, toy, automobile and motorcycle, and molding industry. Through the repairing of moulds, it is possible to reuse the moulds, save the production cost and improve the working efficiency significantly. This technology can also be used to modify the design or size of moulds to reduce the development period.

With unique structure design, it is suitable for repairing of large, medium and small moulds.

| S.No | Parameters Name | Parameters Data |

|---|---|---|

| 1. | Types | Fixed Optical Bench/Hanging Arm/Fixed Optical Bench |

| 2. | 3-axis stroke of work bench | X=300mm, Y=200mm (X, Y can be adjusted manually and Z-axis can be lifted) |

| 3. | Welding wire diameter | 0.1mm ~ 0.8mm |

| 4. | Pulse width | ≤20ms, 0.2 ~ 25ms |

| 5. | Maximum laser power | 180W, 300W |

| 6. | Bearing of work bench | ≤200KG |

| 7. | Power supply | 220V≤10%/50Hz Or 380V≤10%/50Hz |

| 8. | Laser Type | Nd:YAG pulse |

| 9. | Adjusting range of light spot | 0.1~0.3mm |

| 10. | Size of light spot | 0.2–3.0mm |

| 11. | Laser wavelength | 1064nm |

| 12. | Pulse frequency | ≤50Hz |

| 13. | Laser output focus length | 80mm/100mm/120mm(optional) |

| 14. | Laser cooling | Water cooling |

| 15. | Observing system | Microscope (360° adjustable) |

| 16. | Protection gas | One line (xenon) |

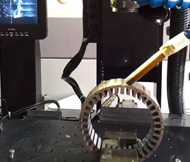

From welding of special gears for small batches of gearboxes, to rack-and-pinion steering gear, differentials, cylinder blocks, suspension arm strengthening ribs and advanced devices at the cutting edge of racing technology, you can depend on us to keep your team in pole position. We weld aluminum alloys, steel and titanium and resolve your high-tech welding issues. Prototype work is frequently undertaken.

From welding of special gears for small batches of gearboxes, to rack-and-pinion steering gear, differentials, cylinder blocks, suspension arm strengthening ribs and advanced devices at the cutting edge of racing technology, you can depend on us to keep your team in pole position. We weld aluminum alloys, steel and titanium and resolve your high-tech welding issues. Prototype work is frequently undertaken.

A well known rally team manufactured a set of hubs for their car which were all but finished when the designers changed a diameter. Cars overcame the problem by adding a layer of titanium 64 all round the internal diameter for the hubs to be re-machined to the new dimension, resulting in no distortion or reduction in strength.

Standard motors have straight plain output shafts, and need gears or actuators welding on. Laser welding is ideal for its accuracy in aligning the gear and welding it firmly in place, and the low heat input avoids damaging the motor. Cars weld front wing trim actuators and gear selector motors for various teams.

Standard motors have straight plain output shafts, and need gears or actuators welding on. Laser welding is ideal for its accuracy in aligning the gear and welding it firmly in place, and the low heat input avoids damaging the motor. Cars weld front wing trim actuators and gear selector motors for various teams.

| S.No | Parameters Name | Parameters Data |

|---|---|---|

| 1. | Wavelength | 1064nm |

| 2. | Max. Single pulse energy | 60J 80J |

| 3. | Average output power | 60W 100W |

| 4. | Focused spot diameter | 0.20-1.5mm (Adjustable) |

| 5. | Pulse width | 1-20ms (Adjustable) |

| 6. | Pulse frequency | 1-20Hz |

| 7. | Protective gas | One Route |

| 8. | Power supply | 220V 50Hz 4.5KW |

| 9. | Dimension | 830*560*1045mm |

The laser spot welding is an important aspect of laser process technology application. The spot welding process is thermal conduction, i.e. the laser radiation heats the surface of work piece, and the surface heat diffuses to the interior through thermal conduction and melts the work piece by controlling the width, energy, peak power and repeating frequency of laser pulse to form specific molten pool. Because of its unique advantage, it is widely used in the process of gold and silver jewelry and welding of mini and small parts.

The laser spot welding is an important aspect of laser process technology application. The spot welding process is thermal conduction, i.e. the laser radiation heats the surface of work piece, and the surface heat diffuses to the interior through thermal conduction and melts the work piece by controlling the width, energy, peak power and repeating frequency of laser pulse to form specific molten pool. Because of its unique advantage, it is widely used in the process of gold and silver jewelry and welding of mini and small parts.

| S.No | Parameters Name | Parameters Data |

|---|---|---|

| 1. | Max. Laser Power | 150W |

| 2. | Laser working medium | Nd: YAG |

| 3. | Laser Wavelength | 1064nm |

| 4. | Single Pulse Max Laser Power | 60J |

| 5. | Feedback Type | Current minus feedback |

| 6. | Single Pulse Width | 0.1ms-20ms |

| 7. | Welding Depth | 0.1-3mm (Depending on materials) |

| 8. | Pulse Frequency | 1-200HZ |

| 9. | Positioning | Red light |

| 10. | Cooling | Water Cooling |

| 11. | Power Consumption | 6KW |

| 12. | Power Supply | Three phase 380V/50HZ |

| 13. | Host dimension(W*D*H) | 1000mm*480mm*1080mm |

| 14. | Chiller dimension(W*D*H) | 40mm*660mm*770mm |

Pulse laser welders are electronically compatible and ideal for voltage sensitive applications. Precision automated or manual welding construction can be performed on electronic/industrial components with a high degree of accuracy, while eliminating the potential hazards of heat damage or thermal stress to complex manufacturing materials.

Pulse laser welders are electronically compatible and ideal for voltage sensitive applications. Precision automated or manual welding construction can be performed on electronic/industrial components with a high degree of accuracy, while eliminating the potential hazards of heat damage or thermal stress to complex manufacturing materials.

Laser welding also ensures a longer life of the component parts.Common laser spot or laser seam welding applications include tool and die repair, complex electronic components, high-precision industrial assemblies, pressure-sensitive hermetic laser seals, and other unique applications.

| S.No | Parameters Name | Parameters Data |

|---|---|---|

| 1. | Laser system | ND-YAG :UW 25W / 5W |

| 2. | Energy share | 3 way |

| 3. | Work station | 45 deg angular welding |

| 4. | View | CCD Monitor |

| 5. | Work bench size | 780mmx950mmx1150 |

For flat plate solar energy collectors, the aluminium sheet and copper tube is thin, traditional welding will cause irregularity in welding depth, blemish, and destroying the covering film of the collector.

For flat plate solar energy collectors, the aluminium sheet and copper tube is thin, traditional welding will cause irregularity in welding depth, blemish, and destroying the covering film of the collector.

Laser welding will solve this problem for its precise locating.

| S.No | Parameters Name | Parameters Data |

|---|---|---|

| 1. | Work station | 2 Nos |

| 2. | Output Head | 2 Nos (rotate automatically, can weld X, Y direction) |

| 3. | Welding wire diameter | 0.1mm ~ 0.8mm |

| 4. | Control | 1064nm |

| 5. | Drive | Servo Motor |

| 6. | Travel | 2350mm x1100mm |

| 7. | Accuracy | 0.05mm |

| 8. | Size | 8500mm x 2200mm x 1580mm |

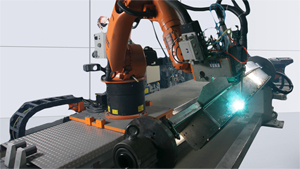

Laser Hybrid welding is a type of welding process that combines the principles of laser beam welding and arc welding. The combination of laser light and an electrical arc into an amalgamated welding process has existed since the 1970s, but has only recently been used in industrial applications.

Laser Hybrid welding is a type of welding process that combines the principles of laser beam welding and arc welding. The combination of laser light and an electrical arc into an amalgamated welding process has existed since the 1970s, but has only recently been used in industrial applications.

There are three main types of hybrid welding process, depending on the arc used: TIG, plasma arc or MIG augmented laser welding. While TIG-augmented laser welding was the first to be researched, MIG is the first to go into industry and is commonly known as hybrid laser welding.

Whereas in the early days laser sources still had to prove their suitability for industrial use, today they are standard equipment in many manufacturing enterprises. The combination of laser welding with another weld process is called a “hybrid welding process”. This means that a laser beam and an electrical arc act simultaneously in one welding zone, influencing and supporting each other.

For welding metallic objects, the laser beam is focused to obtain intensities of more than 1 MW/cm2. When the laser beam hits the surface of the material, this spot is heated up to vaporization temperature, and a vapor cavity is formed in the weld metal due to the escaping metal vapor. This is known as a keyhole. The extraordinary feature of the weld seam is its high depth-to-width ratio. The energy-flow density of the freely burning arc is slightly more than 100 kW/cm2. Unlike a dual process where two separate weld processes act in succession, hybrid welding may be viewed as a combination of both weld processes acting simultaneously in one and the same process zone. Depending on the kind of arc or laser process used, and depending on the process parameters, the two systems will influence each other in different ways.

The combination of the laser process and the arc process results in an increase in both weld penetration depth and welding speed (as compared to each process alone). The metal vapor escaping from the vapor cavity acts upon the arc plasma. Absorption of the laser radiation in the processing plasma remains negligible. Depending on the ratio of the two power inputs, the character of the overall process may be mainly determined either by the laser or by the arc.

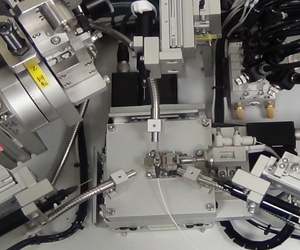

We manufacture & supply an excellent assortment of our Glove Box Welding Machines, which is widely accepted by our clients all across the globe. Our such range is fabricated from high grade material that makes it more reliable and durable. These machines are very efficient as they are built using advanced technology.

We manufacture & supply an excellent assortment of our Glove Box Welding Machines, which is widely accepted by our clients all across the globe. Our such range is fabricated from high grade material that makes it more reliable and durable. These machines are very efficient as they are built using advanced technology.

SUS 304 Thickness 2mm, Circular Type Antechamber, 390mm dia, Length 600mm, Material Stainless Steel SUS 304 Thickness 3mm, Siding Tray: Stainless Steel SUS 304 Inside Surface Brushed Finish, Outside Surface Enameled, Grey. Doors: Material Aluminum, Anodized, Thickness 10mm. Door lock Spindle-Lock, Lifting Mechanism, with inner shelfs Pressure Gauge: Manometer Analog Display Valves: Automatic Valves(KF-25 Vacuum Line/3/8″ refill line) Vacuum/Refill: PLC Automatic Control

Mini Antechamber, SUS 304, thickness 2mm, Length: 300mm, Diameter: 150mm

<10-5mbar- l/s

| S.No | Parameters Name | Parameters Data |

|---|---|---|

| 1. | Laser power | 75 Watts |

| 2. | Beam delivery | 2 way energy share |

| 3. | Control | industrial pc |

| 4. | Drive | Servo Motor |

| 5. | Travel | 300mm x200mm x 100mm |

| 6. | Function | Heat Absorbing Glass |

| 7. | Technique | Glass |

| 8. | Thickness | 2mm, 3mm |

| 9. | Usual Size | 50*108mm, 30*110mm, 90*110mm, 18*110mm, 50*100mm |

| 10. | Size Tolerance | +/- 0.05mm |

| 11. | Color | Clear, Black, Green, Gold |

| 12. | Material | Glass, PVC, ABS |

| 13. | Irt | 700-1300um |

| 14. | UV Transmittance | 313nm |

| 15. | Usage | Electric Welding |

The Pillow Plate (or thermo plate) consists of two steel plates, connected by laser welding. After being welded together, the plate is inflated by using water pressure. The water pressure creates a specific single or double embossed profile – the pillow plate, through which the cooling or heating medium is conducted. While the thickness and the spot pattern is determined by the design pressure.

The Pillow Plate (or thermo plate) consists of two steel plates, connected by laser welding. After being welded together, the plate is inflated by using water pressure. The water pressure creates a specific single or double embossed profile – the pillow plate, through which the cooling or heating medium is conducted. While the thickness and the spot pattern is determined by the design pressure.

Tailored blanks are semi-finished parts, which are typically made from sheets with different alloys, thicknesses, coatings or material properties. After joining, these will be subjected to deep drawing or stamping.

Tailored blanks are semi-finished parts, which are typically made from sheets with different alloys, thicknesses, coatings or material properties. After joining, these will be subjected to deep drawing or stamping.

Tailored blanks are used to make items such as door panels which are thick near the hinges and thin near the lock to withstand different types of loads or corrosion attacks.

They are lighter and often cheaper than conventional sheets. Tailored Blanks are typically made from steel. Aluminium and dissimilar material tailored blanks are also available but less common.

Tailor Welded Blanks (TWB) are welded from different sheets in the butt joint configuration. This is normally achieved by laser welding.

Laser beam welding (LBW) is a welding technique used to join pieces of metal or thermoplastics through the use of a laser. The beam provides a concentrated heat source, allowing for narrow, deep welds and high welding rates. The process is frequently used in high volume applications using automation, such as in the automotive industry. It is based on keyhole or penetration mode welding.

Along with cost reduction, weight reduction, and increased performance there are many advantages to using tailor welded blanks.

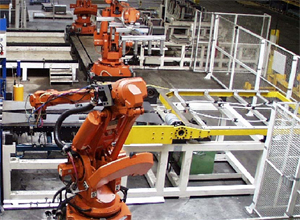

The system concept of the JENOPTIK-VOTAN BIM series is based on a beam guide inside the robot. This allows using CO2 lasers with a power of up to 5 kW without having to use a complex external beam guide that often causes collisions. At the same time, the equidistant beam path prevents the laser beam from pumping, ensuring a stable beam quality.

This approach makes the Jenoptik system an optimized tool for cutting of all 3D plastic parts of a vehicle, for example inner doors or bumpers. Due to its high flexibility, JENOPTIK-VOTAN BIM is the ideal, virtually wear-free tool for processing of a variety of working parts even if you have only one laser machine, because you don’t need the special cutting dies as during the conventional processing.

In order to expand the applications of the laser beam welding, Jenoptik has developed a welding technique with free radiating diode lasers. Diode lasers have been used as pump sources in disk lasers for years and are used by Jenoptik as direct emitters, too.

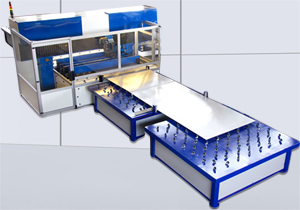

YAG 500W Sheet Metal Laser Cutting Machine integrates optical, mechanical, and electricity in one, which adopts laser, computer control technology and high-performance CNC laser power system. The cnc laser cutting machine is applied to cut stainless steel, carbon steel, alloy steel, spring steel, aluminum, silver, copper, titanium and some metal plate and pipe.

Widely used in sheet-metal structure, high-low-voltage electrical cabinet production, hardware, knife-volume, production of advertising signs, metal crafts, decoration aviation, mechanical parts, electical meter, sawblades, spring-chip and other industries.

| S.No | Parameters | Range |

|---|---|---|

| 1. | Medium of Laser | Nd: YAG |

| 2. | Laser Output Power | 500W |

| 3. | Cutting area(mm) (length × width): | 3000mm×1500mm |

| 4. | Max cutting speed(m/min) | 8 m/min, 10 m/min |

| 5. | Cooling way | Water cooling |

| 6. | Pulse Repeated Frequency | 0-300Hz |

| 7. | Min Line Width | 0.12mm |

| 8. | Laser Wavelength | 1064nm |

| 9. | Working Power | 380V/50Hz/50A |

| 10. | Continuous Working Time | 24 hours |

| 11. | Weight | 3000kg |

| 12. | Outline Size(mm) | 4270mm×2480mm×1400mm (length×width×height) |

Adopt cantilever flying optics structure. It is available to load and unload from three directions. Very good operator-machine access ability. Sheet material over 3meter by 1.5meter can also be put on the table.

| S.No | Parameters | Range |

|---|---|---|

| 1. | Working Area | 3000mm×1500mm |

| 2. | X Axis Travel Distance | 3030mm |

| 3. | Y Axis Travel Distance | 1520mm |

| 4. | Z Axis Travel Distance | 105mm |

| 5. | Power of Fiber Laser | 500W – 4000W |

| 6. | Accuracy | ±0.05mm |

| 7. | Repeatability | ±0.02mm |

| 8. | Ideal speed | 100m/min |

| 9. | Max cutting speed | 60m/min |

| 10. | Acceleration (X, Y axle) | 1.5g |

CO2 laser brings sophistication in high-speed laser cutting onto a new level, creating enhanced production with superior speed, accuracy, and part quality. CO2 lasers are designed by using innovative linear drive motor technology to allow maximum speeds, even in small notches or narrow contours.

It provides previously unseen high-speed performance with regard to machining dynamics, contour accuracy, and process safety. Finn-Power L6 will process sheet sizes up to 1565 mm x 3074 mm. With 4 kW or even 5kW of laser power, it enhances laser cutting for various material thickness and material types.

The rigid machine frame provides a solid base for stable beam delivery optics and the high-speed drive system. This unique frame design accommodates highest acceleration and deceleration rates without compromise.

HIGH POWER CO2 laser has a compact design with the resonator and CNC built into the structure. The positioning of the shuttle tables is possible on two sides of the machine. This is beneficial when plant layout or production flow require system layout flexibility.

| S.No | Parameters | Range |

|---|---|---|

| 1. | Work Size | 60″ x 120 |

| 2. | Repeatability | 0.001″ |

| 3. | Positioning Accuracy | +/0.004″ per 120″ of travel |

| 4. | Positioning Speed | 7900ipm, combined axis |

| 5. | Laser Power | 2.0kw / 2.5kw / 4.0kw / 6.0kw |

| 6. | Controller | SINUMERIK 840D |

| 7. | Lens | 5″ and 7.5″ FL quick cartridge |

| 8. | Table | Dual shuttle type pallets |

It incorporates space saving design and ease of use. Its high cutting speed and very low operating cost makes the most affordable system on the market. The Lasersystem can cut both framed and frameless stencils, without requiring any changeover. The light weight motion system allows excellent positioning accuracy while maintaining cutting speeds that are the highest in its class.

It incorporates space saving design and ease of use. Its high cutting speed and very low operating cost makes the most affordable system on the market. The Lasersystem can cut both framed and frameless stencils, without requiring any changeover. The light weight motion system allows excellent positioning accuracy while maintaining cutting speeds that are the highest in its class.

| S.No | Parameters | Range |

|---|---|---|

| 1. | Wavelength | 1064 nm |

| 2. | Output power | 150-250W |

| 3. | Power supply | 380V +/- 15% 50/60 Hz 3ph – 9 KW |

| 4. | Dimensions | 1270x2100x2173h mm |

| 5. | Working Area | 600x600x400h* mm |

| 6. | Repeatibility | +/- 0,02 mm |

| 7. | Cooling System | Water |

| 8. | Weight | 1200 Kg |

The laser optics and CNC (Computer Numerical Control) are used to direct the material or the laser beam generated. A typical commercial laser for cutting materials involved a motion control system to follow a CNC or G-code of the pattern to be cut onto the material. The focused laser beam is directed at the material, which then either melts, burns, vaporizes away, or is blown away by a jet of gas, leaving an edge with a high-quality surface finish. Industrial laser cutters are used to cut flat-sheet material as well as structural and piping materials.

| S.No | Parameters | Range |

|---|---|---|

| 1. | Laser Wavelength | 1070-1080nm |

| 2. | Laser Generator | Fiber laser |

| 3. | Freedom of motion in space | 5 axis |

| 4. | Positioning | Red light |

| 5. | Laser Power | 500W |

| 6. | Continuous Working Time | 24 hours |

| 7. | Max. Cutting Thickness | ≤ 6 mm(According to materials and auxiliary gas) |

| 8. | Laser Power Stability | ≤ ± 3 % |

| 9. | Pulse Width | 0.1~20 ms |

| 10. | Cooling | Water Cooling |

The 3D laser technology can produce extremely accurate and complex laser cut geometry on angle, box, channel, pipe and tube, offering increased flexibility as well as rapid turnaround times on high quality products.In the laser cutting workshop is cutting a sheet metal molded parts, products made from bent sheet metal and planar shapes (small batch and mass production)

Note: We can design and manufacture fiber laser cutting machine as your specific requirements. And you can send us samples for free cutting.

| S.No | Parameters | Range |

|---|---|---|

| 1. | Laser Wavelength | 1070-1080nm |

| 2. | Laser Generator | German IPG Fiber laser |

| 3. | Freedom of motion in space | 6 axis |

| 4. | Positioning | Red light |

| 5. | Laser Power | 500W |

| 6. | Continuous Working Time | 24 hours |

| 7. | Max. Cutting Thickness | ≤ 6 mm(According to materials and auxiliary gas) |

| 8. | Laser Power Stability | ≤ ± 3 % |

| 9. | Pulse Width | 0.1~20 ms |

| 10. | Cooling | Water Cooling |